Safety critical cyber-physical systems depend highly on a complex supply chain. Industries such as the automotive, aerospace and heavy machinery count on these supply chains which span across the globe. A fundamental issue faced by such systems is ensuring the integrity of both the cyber information and the physical parts that move throughout the supply chain. Since the manufacturer and consumer are at times geographically separated, there are various challenges in ensuring that physical parts arriving from the manufacturer to the consumer are unmodified and untampered with in-transit. Any attempt of breach or counterfeiting is a grave concern for sensitive supply chains. For industries such as aerospace and automotive, this poses not only risk of intellectual property theft but also risk of system failure and loss of life due to the accidental use of poor-quality fake parts. It is difficult to guarantee the integrity and identity of physical parts as they move through a distributed supply-chain.

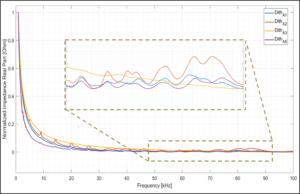

In order to identify physical parts, physical identifiers (such as serial numbers, barcodes, etc.) are traditionally stored in data banks. However, a data breach can easily compromise the integrity of the physical parts. A potential solution to this problem is to use the unique electromechanical impedance measurement and link the cyber information of a part to its intrinsic physical information. This would assist in creating a robust and tight distributed supply-chain. This linked cyber-physical information can then be used to create an unclonable physical identity which would be difficult or to some degree impossible to steal or tamper with. This research can help link unique cyber-physical information of a part to its structural information. Furthermore, this research can be extended to in-transit monitoring of the parts.